By simulating real-world conditions, we turned complex HVAC choices into confident design decisions.

How do you renovate a century-old auditorium for today’s audiences without compromising comfort? At Clemson University’s Tillman Auditorium, Newcomb & Boyd used Computational Fluid Dynamics (CFD) analysis to answer that question.

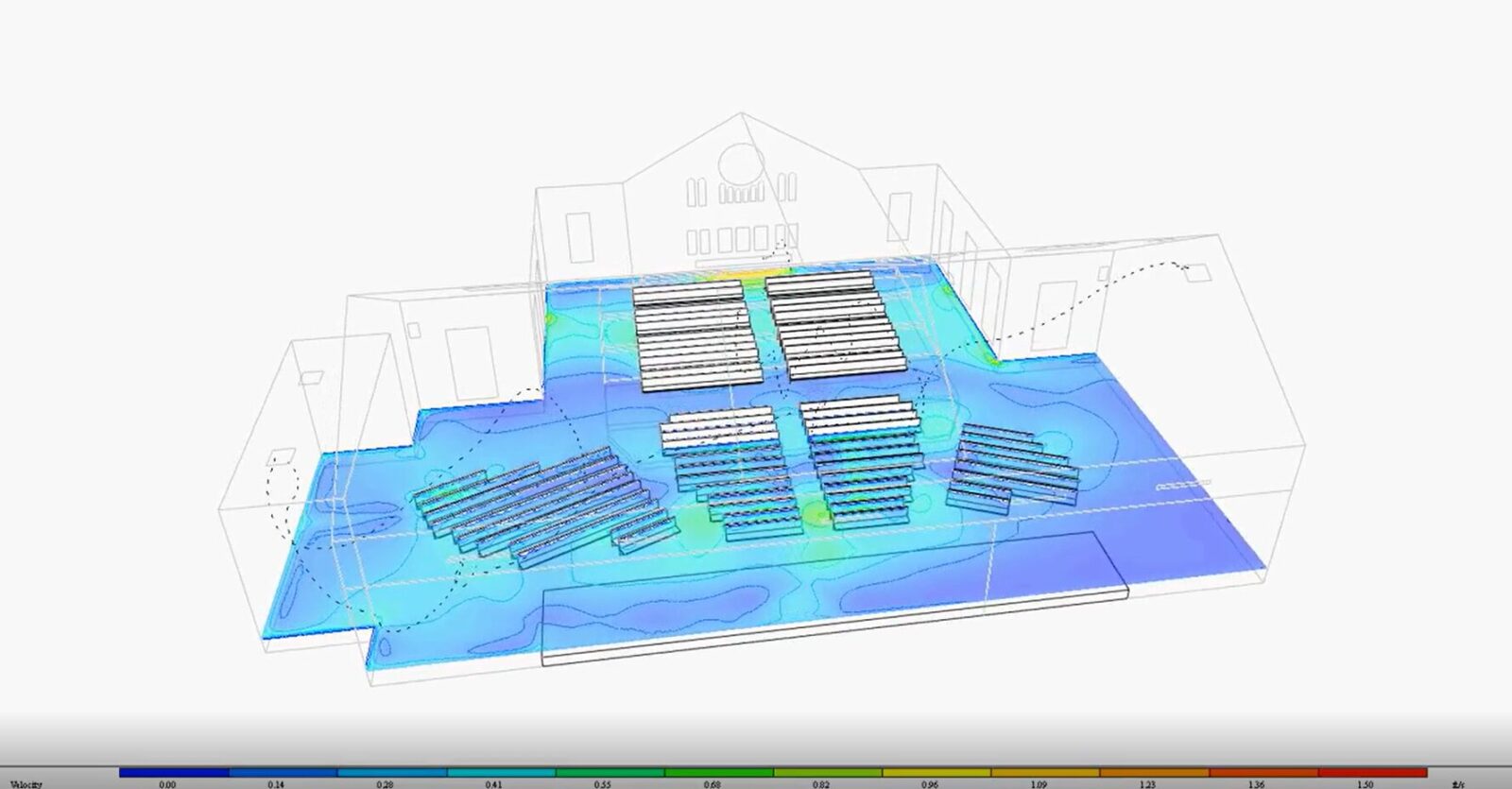

Large spaces like auditoriums pose unique challenges. High peak occupancy, fluctuating drafts, and temperature stratification can leave audiences uncomfortable. To solve this, our team compared various HVAC distribution strategies that combined overhead diffusers with underfloor air distribution.

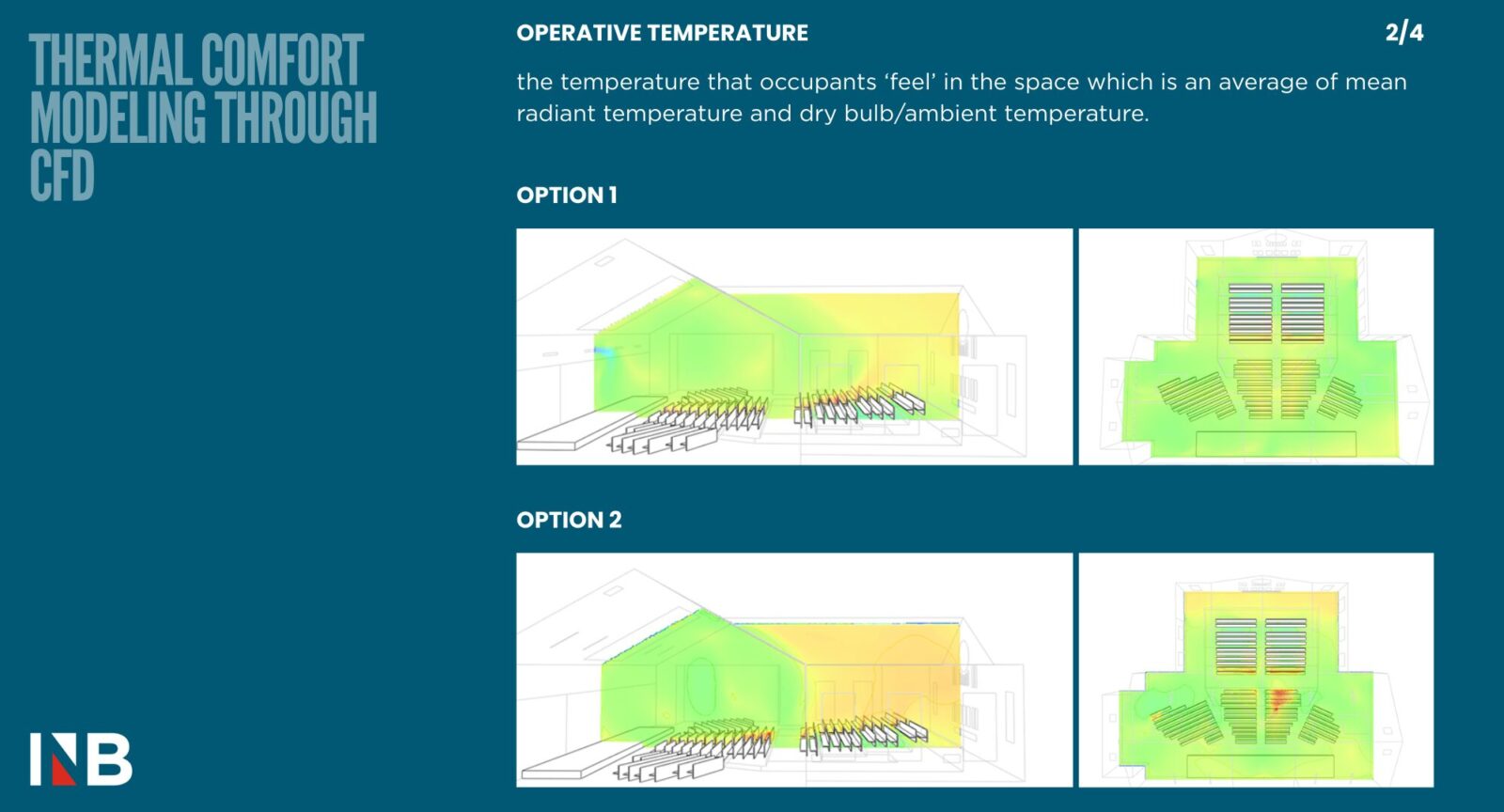

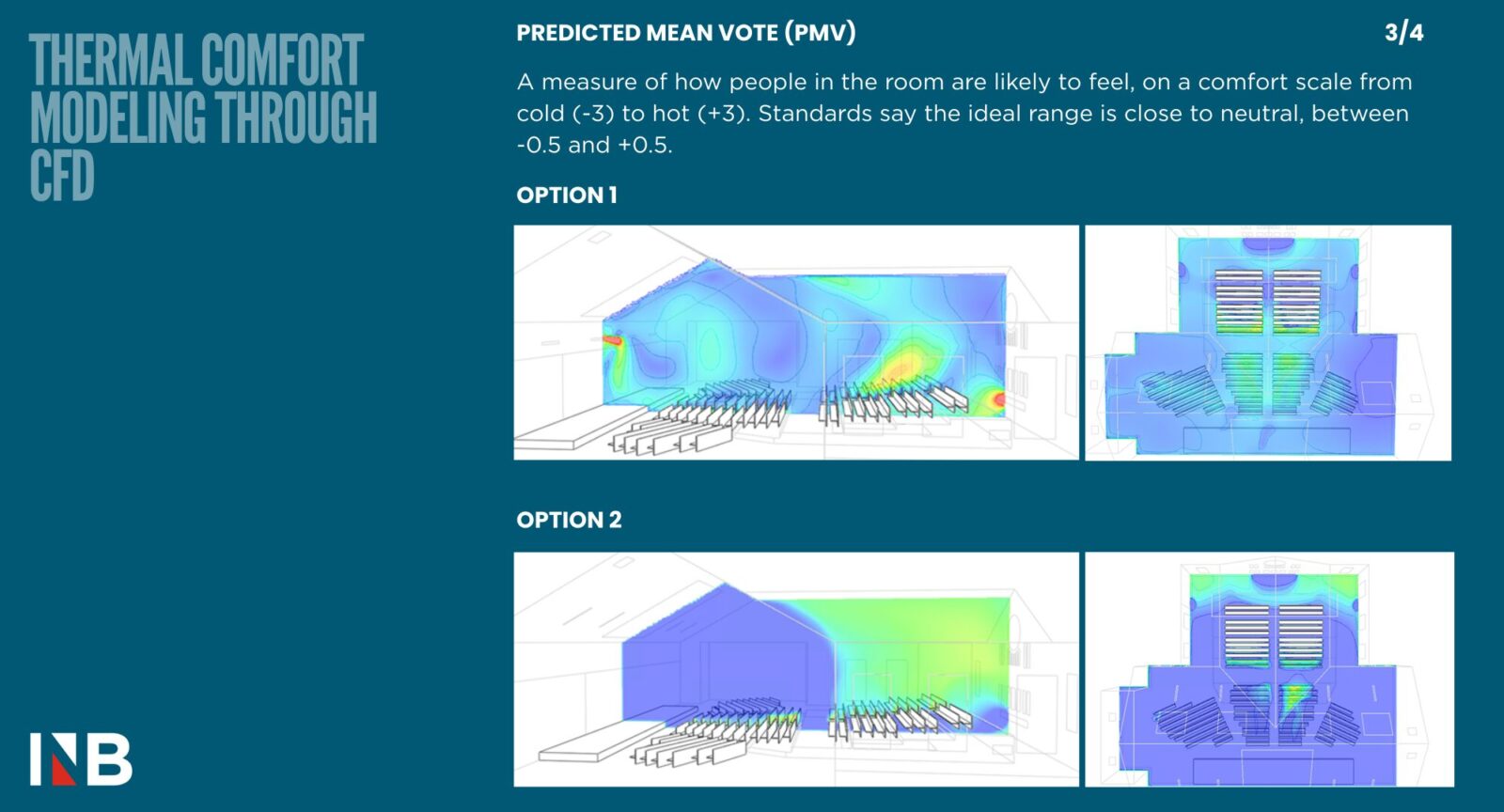

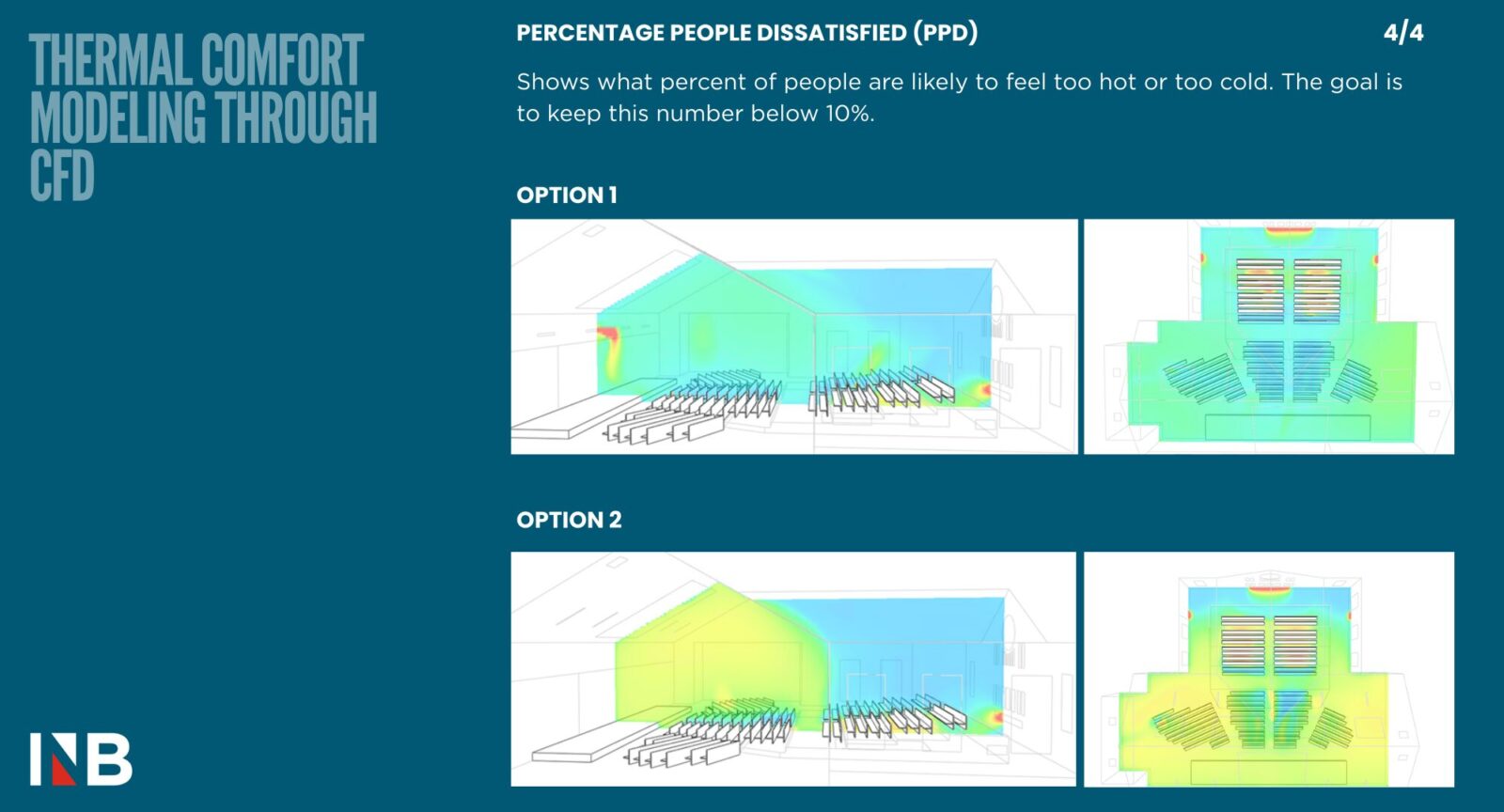

By simulating real-world conditions, CFD helped us measure thermal comfort using industry standards such as Operative Temperature, Predicted Mean Vote (PMV) and Percentage People Dissatisfied (PPD). The results guided design refinements that improved airflow, balanced temperatures, and maximized occupant comfort before construction began.

Takeaway

This project demonstrates how digital analysis tools can bring clarity to complex design decisions and can be incorporated in the design workflow. CFD not only validated the HVAC design, but also created a path for future optimization during construction and operation.

Thoughtful use of CFD transforms the way we design for human experience. This ensures that historic spaces like Tillman Auditorium continue to inspire, and do so comfortably, for generations to come.

Particle Tracking

What is Particle Tracking?

Think of particle tracking like putting tiny, invisible balloons into the air and watching how long they float around before being pulled back into the HVAC system. Some move quickly through the space, while others get stuck swirling in corners or under seats.

Why does it matter?

If air particles linger too long, that signals a “dead spot” where air is not circulating effectively. In those areas, heat can build up, the air can feel stale, or contaminants may accumulate.

How it connects to Tillman Auditorium

In a packed auditorium, good airflow is about more than comfort. It is also about keeping the environment healthy and consistent across hundreds of seats. Particle tracking helps engineers see where the HVAC system may struggle and adjust the design so that air moves evenly, reducing drafts and stagnant zones.

In short: Particle tracking shows us how fresh air actually behaves in a space, helping us fine-tune designs for comfort, health, and performance.

Ronnie Haldar

Ronnie is skilled in the development of energy models for new and renovated facilities. His expertise includes numerous projects, including workplace and higher education facilities. While in graduate school, Ronnie created a conceptual design for a future shared Living Manufacturing Facility to be located on the Resource Innovation Campus, owned by the City of Phoenix. Throughout his career, Ronnie has demonstrated an adeptness with various design software, including Trane Trace, EnergyPlus, Rhinoceros+Gasshopper as well as knowledge of programming in C++ & Python and parametric analysis.

Ronnie presented at the 2025 ASHRAE Conference for Integrated Design, Construction & Operations on “CFD Analysis as a decision-making tool for an auditorium HVAC design”.