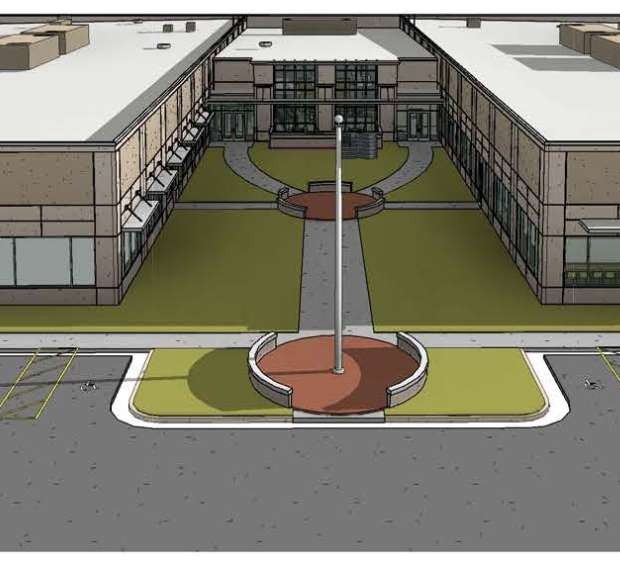

Rinnai America Corporation Manufacturing Facility

Under Construction: A 111,000 square foot manufacturing facility, a 145,000 square foot warehouse, and a 22,500 square feet of office space to support a manufacturing process.

Makita Corporation Press Room

Addition of a press room to Makita Corporation, a portable electric hand tool manufacturing facility.

JVC Corporation

Multiple projects for JVC Corporation, a compact disc production facility, including the original 70,000 square foot facility; a 40,000 square foot expansion of the storage warehouse; a 67,800 square foot addition with a K-room and cleanrooms; addition of a chiller to a distillation tower system and modification to the solvent recovery distillation system; retrocommissioning of ISO 7 cleanrooms; addition of a 15,600 square foot cleanroom; and modifications to ISO 6 cleanrooms to accommodate new processing equipment.

ZLB Plasma Services

ZLB Plasma Services is a critical 24/7 plasma processing facility housing laboratories, an ISO 7 cleanroom, and administrative areas.

Electrical

The project included an 880 kW, natural gas fueled standby engine-generator set.

Suniva Manufacturing Plant

Suniva’s solar cell manufacturing facility is a two-line production and research facility including two ISO 8 cleanrooms, high purity water systems, chemical delivery systems, a chemical bunker, high purity piping, and 15,000 square feet of office space. Additional work includes a 40,000 square foot expansion to accommodate a third and fourth production line in the solar cell manufacturing facility.

YKK AP America, Inc.

A melting and casting plant addition for YKK, as well as aluminum curtain wall and storefront manufacturing facility, including casting, extrusion, anodizing, painting, and fabrication. The facility includes 2000 hp compressed air system and distribution. Additional work includes renovation to accommodate fabrication of aluminum, windows, and doors, and Phase II expansion of a previously designed aluminum smelting house. The expansion included an additional storefront and window casing profile type extrusion line, automated conveyor system, and painting line with cleaning, pretreatment, painting and baking oven with industrial ventilation. The facility also includes space for warehouse and fabrication of final products, including shipping.

Southeast Toyota at Westlake Vehicle Processing Facility

The Vehicle Processing Facility includes ten buildings handling 250,000 vehicles per year, on a 250 acre site, with another 250 acres for future expansion.

Audio- Visual

Facility-wide paging system for the automobile processing facility.

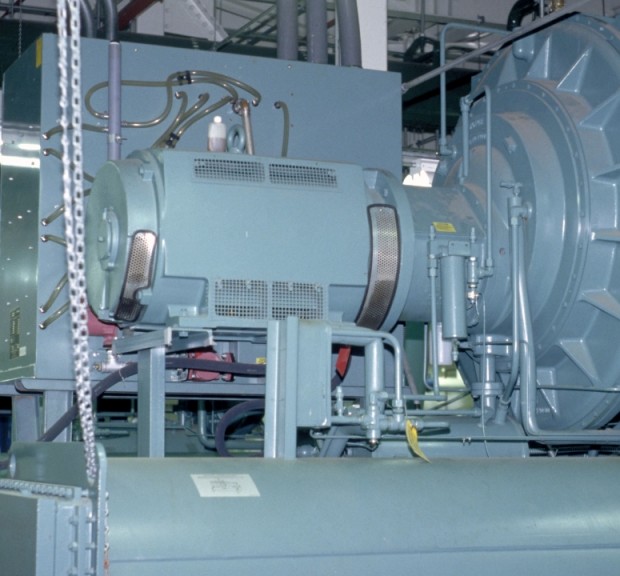

Ortho Clinical Diagnostics

Multiple projects for Ortho Clinical Diagnostics including two new central chilled water plants to serve multiple interconnected buildings in a research complex housing laboratories, an animal colony, manufacturing, and administrative functions. Work includes demolition of multiple remotely located chillers and installation of new chillers located in the central plants, a chilled water distribution system, and elimination of CFC refrigerants. The plants are designed to accommodate a 120,000 square foot expansion; schematic drawings and airflow diagrams for four existing air handling systems serving ISO 7 cleanrooms, including air filtration, room pressurization, and ventilation requirements, for presentation to the FDA for new product licensing; and expansion of the RhoGAM process production facility including ISO 7 and ISO 8 cleanrooms requiring low temperature refrigerants, bulk nitrogen, compressed air, clean steam, and water for injection systems for pharmaceutical manufacturing.

CSL Plasma Facility Addition and Renovation

Addition to and partial renovation of CSL Plasma, a critical 24/7 blood plasma processing facility. The 37,350 square foot addition includes laboratory space providing redundancy to the existing processes, administrative space, a large centralized break room, and a centralized loading dock.